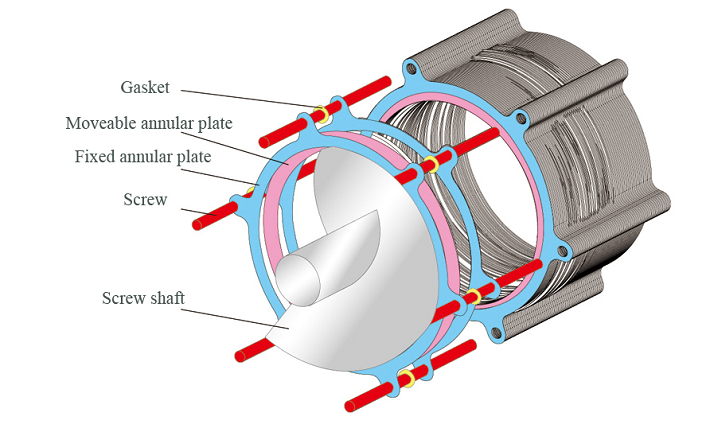

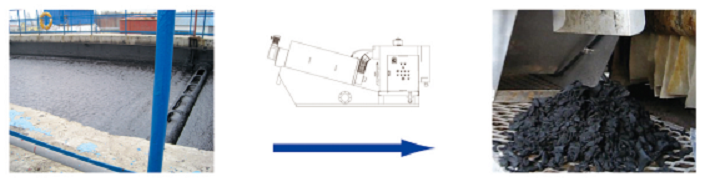

Dewatering screw press which uses the screw extrusion principle is a new type of solid-liquid separation device. It reaches the goal of extrusion dewatering sludge by the powerful extrusion pressure of changing the screw diameter and distance, and the tiny spacing between moveable annular plates and fixed annular plates.

Product Introduction:

Dewatering screw press which uses the screw extrusion principle is a new type of solid-liquid separation device. It reaches the goal of extrusion dewatering sludge by the powerful extrusion pressure of changing the screw diameter and distance, and the tiny spacing between moveable annular plates and fixed annular plates.

Structure Principle:

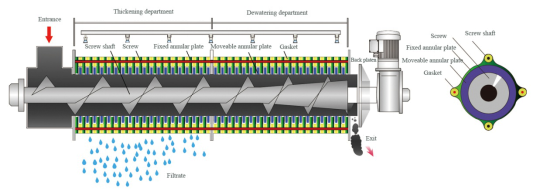

The main body of dewatering screw press (Volute Sludge Dewatering) is made of multiple fixed annular plates and moveable annular plates with the screw shaft running through it. The front part is thickening department and the ending part is dewatering department. It can thicken and dewater sludge in one box, and has taken place of the traditional filter clothes and centrifugal filtration method for its distinctive filter model.

Dewatering Principle:

Sludge will be transported to the dewatering department after being thickened in the thickening department. In the advancing process, great pressure has been produced because of the gradually decreasing filter spacing and screw distance, and the back platen clogging. Then the volume decreases continuously, and the purpose of fully dewatering will be achieved.

Advantages:

1. Using scope widely

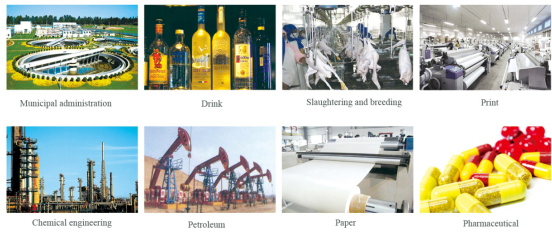

It can be widely used to dewater sludge of municipal administration wastewater, food, drink, slaughtering and breeding, print, petrochemical engineering, paper, leather and pharmaceutical.

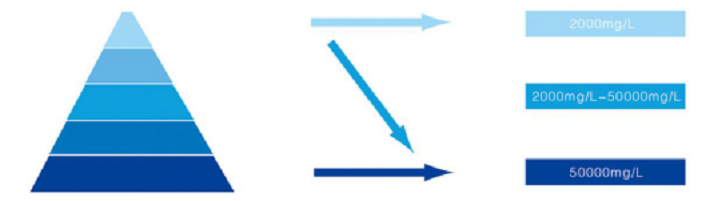

The distinctive dewatering principle makes it possible that the device can be used for high or low density sludge, from 2000mg/L on, which has become the foundation of the low density sludge direct dewatering.

Innovative structure design makes it possible that the device can be used for all kinds of sludge with high or low density, especially the sludge with oil, and it can be named the invincible opponent to dewater the sludge with oil.

2. The device cannot be clogged easily

Special dynamic and static rings make the device not easily clog. Then there is no need to wash abundantly for preventing filter spacing being clogged. So it has reduced the number of water for washing and burden of inside circling, and solves the clogging problems that the traditional dewatering devices bring to the company.

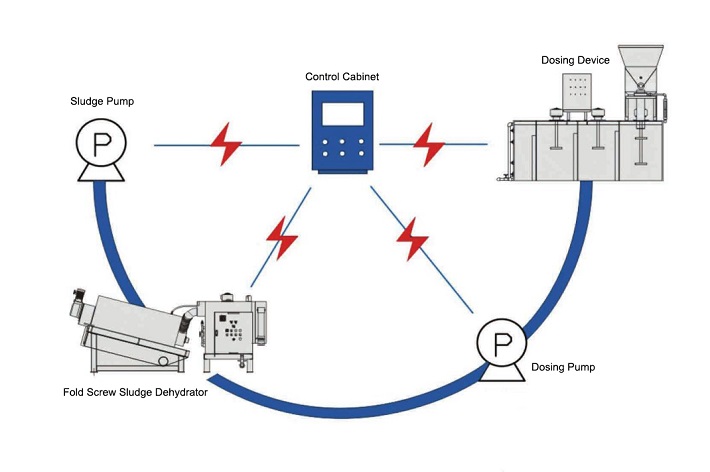

3. Operating continuously and automatically

Volute Sludge Dewatering can control its operation automatically including pumping out sludge, putting in fluids and discharge sludge. The device can operate through the team work of electrical cabinet, chemical feeder, mud pump and dosing pump without manual operation. The device will be clogged, filters running irregularly, or other situations that can affect the safety cannot take place during the whole procedure. Daily maintenance of the machine can be done easily and conveniently. And it can work continuously all day without manual operation. It makes the dream that sludge dewatering can operate continuously and automatically come true firstly and truly.

4. Operation costs can be saved

The integration overall design, compact design, saving operation costs greatly;

Low speed spiral pressing technology makes the power consumption reduced greatly;

The device cannot be clogged, which can reduce cleaning water greatly;

Operation automatically all day can reduce manual costs greatly;

So, Volute Sludge Dewatering is a new type of energy saving and environmental protection device that can truly consistent with national policy.

5. No secondary pollution

The rotation speed of screw shaft is about 2 to 3 revolutions per minute, and the rotation has no vibration and little noise. The volute has the self-cleaning function, cannot be clogged, just need a little water to clean, and has no secondary pollution. The sludge is done in such a slow state and the bad smell is not diffused, which can create a very comfortable operation surrounding.

6. Flexible and durable frame

This machine’s design is quite flexible because it uses machinery to extrusion dewatering directly and do not need large drum frame. Almost all the frame is made of stainless steel and only the screw shaft and moveable annular plates should be replaced, which can contribute to a long service life and durable in use.

7. Saving engineering investment

Volute Sludge Dewatering has the function of thickening sludge. It can deal with the aerobic sludge in the aeration tank directly. So it does not need thickening storage unit, which can reduce the floor space of sewage treatment facilities and construction costs.

8. Improving phosphorus removal function

Sludge will be dewatered in the aerobic situation, so in the sludge thickening tank or storage tank, traditional phosphorus sludge outlet of anoxic or anaerobic situation cannot happen. Then the phosphorus removal function of the sludge treatment system will be improved.

Application:

Widely used to dewater sludge of municipal administration wastewater, food, drink, slaughtering and breeding, print, petrochemical engineering, paper, leather and pharmaceutical.

Thank you for your interested in ShuangFa Machinery. If you have a question about our products, we'd like to hear from you. Please fill out the email form below or call us directly on +15037125671(WhatsApp), won't share your name, address or phone number with anyone. We're passionate and want to help any way we can. Thanks for taking the time to get in touch with us.

If you are interested in our products, please leave us your email. We will send you the latest product information at irregular intervals.

+86-374-8621628

+86-374-8621628 info@filterpresschina.net

info@filterpresschina.net Hexie Road, East Industry Park, Yuzhou City, Henan Province.

Hexie Road, East Industry Park, Yuzhou City, Henan Province.